#2

TOTAL VERIFIED CUTS IN THIS SECTOR AMOUNTS TO – 92 059 346 t CO2

Heat and power generation

Heat and power generation

Distribution of Energy Efficient Light Bulbs in Public and Private Sectors of Ukraine

The purpose of the project is to improve the energy efficiency of Ukraine’s lighting stock by distributing up to 210 926 791 compact fluorescent lamps (CFLs) to Ukrainian clients from the private and public sectors within 14 years.

Details of events/modernization:

The number of distributed CFLs is as follows:

- 2 926 791 CFLs (total) с 01.01.2008 по 01.01.2011;

- 8 000 000 CFLs in 2011;

- 20 000 000 CFLs (annually) from 01.01.2012 till 31.12.2021

Heat and power generation

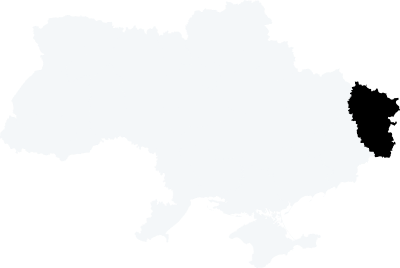

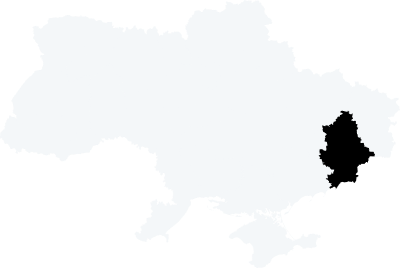

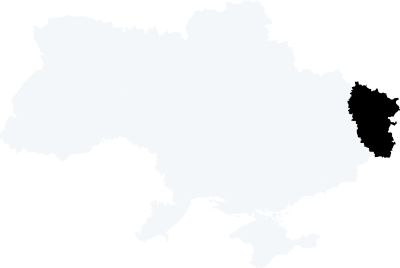

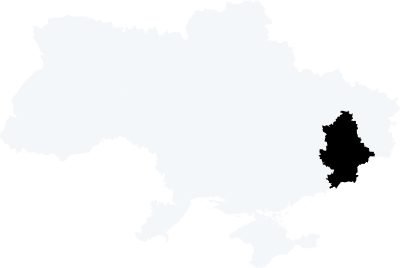

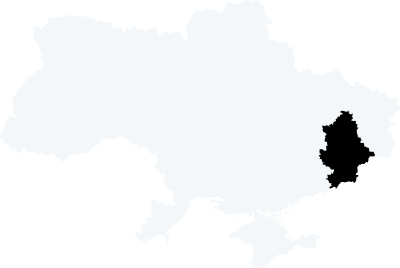

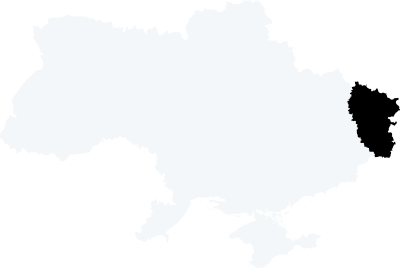

Reduction of Greenhouse Gas Emissions by Stabilization and Demolition of Ltd. “PROMINVESTEKOLOHIIA” Waste Heaps Located near Krasnodon City and Izvaryne Urban Village, Luhansk Region

The purpose of the project is the demolition of dumps of mines No. 17, No. 6-bis “Izvarino”, mines “Vostochnaya”, mines No. 134, mines No. 5, mines No. 2, mines No. 2-bis. As a result of the project implementation, it was planned to eliminate the possibility of spontaneous combustion of waste heaps. This part of the project is unprofitable, so the joint implementation mechanism was one of the critical factors of the project from the very beginning, and the financial benefit under this mechanism was considered one of the reasons for the implementation of the project.

Details of events/modernization:

- Demolition of rock with special equipment, loading onto vehicles and further transportation.

- Direction of demolition products to boiler houses for burning as fuel. Thus, the rock in the dumps is completely utilized, and the resulting coal has replaced the coal that was mined underground.

Heat and power generation

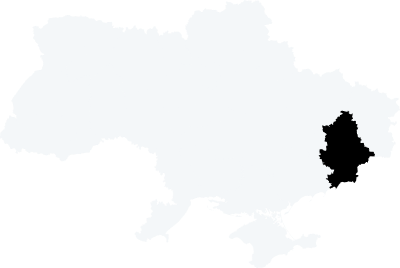

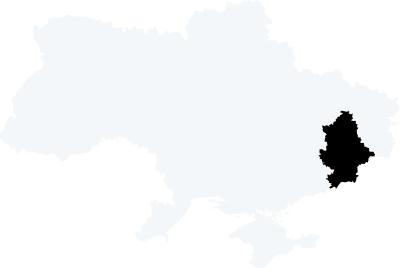

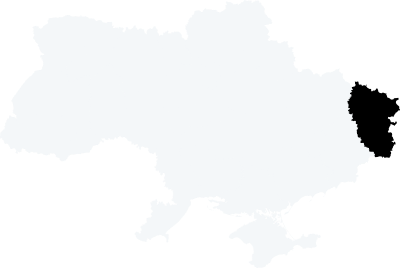

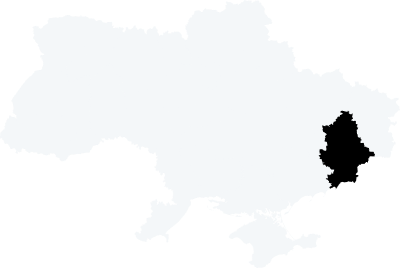

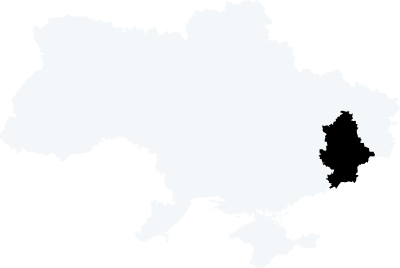

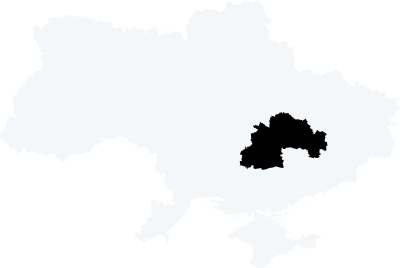

Reduction of Greenhouse Gas Emissions by Stabilization and Demolition of Ltd “PROMINVESTEKOLOHIIA” Waste Heaps Located near Sverdlovsk City and Hirne, Zakhidnyi and Talove Urban Villages, Luhansk Region

The purpose of the project is the demolition of dumps of mine No. 35, mine Karshin, mine No. 30, mine No. 5-bis, mine No. 9, mine No. 3-80, mine No. 31-32. As a result of the project implementation, it was planned to eliminate the possibility of spontaneous combustion of waste heaps. This part of the project is unprofitable, so the joint implementation mechanism was one of the critical factors of the project from the very beginning, and the financial benefit under this mechanism was considered one of the reasons for the implementation of the project.

Details of events/modernization:

- Demolition of rock with special equipment, loading onto vehicles and further transportation.

- Direction of demolition products to boiler houses for burning as fuel. Thus, the rock in the dumps is completely utilized, and the resulting coal has replaced the coal that was mined underground.

Heat and power generation

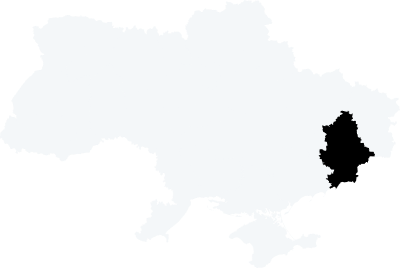

Reduction of Greenhouse Gas Emissions by Stabilization and Demolition of Ltd. “PROMINVEST-EKOLOHIIA” Waste Heaps Located near Mykhailivka, Leninske and Yasynivskyi Urban Villages, Luhansk Region

The purpose of the project is the demolition of dumps of mine No. 35, mine Karshin, mine No. 30, mine No. 5-bis, mine No. 9, mine No. 3-80, mine No. 31-32. As a result of the project implementation, it was planned to eliminate the possibility of spontaneous combustion of waste heaps. This part of the project is unprofitable, so the joint implementation mechanism was one of the critical factors of the project from the very beginning, and the financial benefit under this mechanism was considered one of the reasons for the implementation of the project.

Details of events/modernization:

- Demolition of rock with special equipment, loading onto vehicles and further transportation.

- Direction of demolition products to boiler houses for burning as fuel. Thus, the rock in the dumps is completely utilized, and the resulting coal has replaced the coal that was mined underground.

Heat and power generation

Rehabilitation and technical re-equipment of Starobeshivska thermal power plant of the OJSC "Donbasenergo"

The purpose of the project is to improve fuel efficiency and reduce greenhouse gas emissions compared to the baseline scenario

Details of events/modernization:

- The existing coal-fired boiler at unit No. 4 with a steam capacity of 640 t/h was replaced with a circulating fluidized bed boiler (a highly efficient environmentally friendly technology for burning low-quality fuel and waste from coal processing plants) with a steam capacity of 670 t/h, which burns anthracite sludge.

- The installed capacity of the power unit was increased from 175 MW to 210 MW with a planned increase in efficiency from ~83% to 90.3%.

- Block No. 7 was reconstructed and technically re-equipped, including the modernization of the boiler unit with the replacement of the steam drum, the replacement of smoke exhausters, the modernization of electrical equipment, and the modernization of the control system.

- Boiler burners have been upgraded.

- Partial replacement of flue water heating screens was carried out.

- Replacement of steam pipelines on boiler units.

- Technical re-equipment of superheaters was carried out.

- Improving the lining of boilers using modern materials.

- Improving thermal insulation of pipelines using modern materials;

- Modernization of air heaters was carried out.

- Implemented:

- modernization of the main combined powder burners;

- replacement of boiler furnace screen panels;

- restoration of the boiler furnace lining;

- restoration of thermal insulation of the boiler furnace;

- rehabilitation of the ignition tape of the boiler;

- replacement of tubular air heater cubes (TVH);

- reconstruction and replacement of packages of the third and fourth stages of the convective superheater and inlet (lower) collectors;

- replacement of packages of cold convective superheater;

- replacement of the third stage of the primary circuit superheater;

- replacement of packages of the input stage of the secondary superheater;

- replacement of the screen superheater;

- replacement of water economizer packages;

- replacement of rotor blades of the low-pressure turbine rotor;

- modernization of the turbine low pressure cylinder;

- replacement of mechanical and diaphragm seals on high and low pressure cylinders.

Heat and power generation

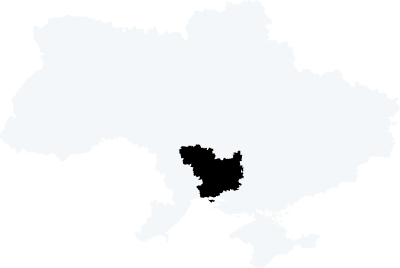

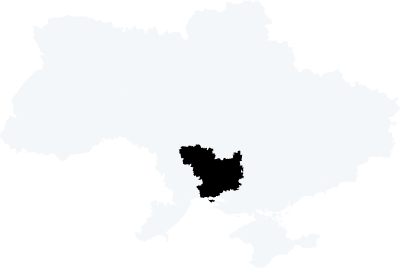

Modernization of the Heat Supply System in Mykolaiv Region

The purpose of the project is to modernize the heat supply system by replacing old boilers with new ones, with a complete modernization of boiler equipment. Including modernization of water treatment and installation of metering systems.

Details of events/modernization:

- Replacement of boiler units, pcs.: 20

- Replacement of burners, pcs.: 6.

- Installation of counters, pcs.: 119.

- Replacement of heat supply networks, m: 945.7.

- Modernization of boiler units, pcs.: 2.

- Introduction of flow control modules and weather-dependent boiler control, pcs.: 1.

- Restoration of the lining and laying of insulation.

- Chemical washing and cleaning.

- Modernization of heating systems, installation of pre-insulated pipes.

- Installation of modern gas and heat metering systems.

Heat and power generation

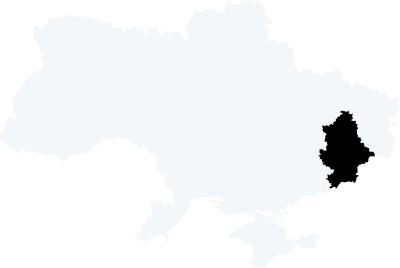

Implementation of the Energy Efficiency Measures and Reduction of Greenhouse Gas Emissions into the Atmosphere at SS “Coal Mine Toretska”, SE “Dzerzhinskugol”

The purpose of the project is to extinguish and stabilize the dumps, which are under the jurisdiction of the mine “Toretskaya” SE “Dzerzhinskugol”, located in the city of Dzerzhinsk, Donetsk region. Project activities will reduce greenhouse gas emissions into the atmosphere. The activity of the project is to stabilize the waste heap with the use of vermiculite material.

Details of events/modernization:

- Comprehensive modernization of coal mining equipment and technologies provided for by the comprehensive modernization within the framework of the JI project led to an increase in production efficiency and, as a result, a reduction in energy consumption during coal mining.

- Implementation of technology for extinguishing dumps at SE “Dzerzhinskugol” by isolating hot spots and supplying oxygen to the burning rock. As a result, combustion has ceased, and the possibility of re-ignition is minimized. Implementation of effective monitoring of dumps, a program that provides for monthly monitoring of waste heaps, as well as urgent extinguishing measures in case of an emergency (control points for exceeding the permissible temperature). According to conservative principles, GHG emissions from the dump burning process are included in the emission reduction calculations in case of re-ignition during project implementation.

Heat and power generation

Implementation of the Energy Efficiency Measures and Reduction of Greenhouse Gas Emissions into the Atmosphere at State Enterprise “Dzerzhinskugol”

The purpose of the project is to extinguish and stabilize the dumps, which are under the control of the Severnaya and Yuzhnaya mines of SE Dzerzhinskugol, located in the city of Dzerzhinsk, Donetsk region. Project activities will reduce greenhouse gas emissions into the atmosphere. The activity of the project is to stabilize the waste heap with the use of vermiculite material.

Details of events/modernization:

- Comprehensive modernization of coal mining equipment and technologies provided for by the comprehensive modernization within the framework of the JI project led to an increase in production efficiency and, as a result, a reduction in energy consumption during coal mining.

- Implementation of technology for extinguishing dumps at SE “Dzerzhinskugol” by isolating hot spots and supplying oxygen to the burning rock. As a result, combustion has ceased, and the possibility of re-ignition is minimized. Implementation of effective monitoring of dumps, a program that provides for monthly monitoring of waste heaps, as well as urgent extinguishing measures in case of an emergency (control points for exceeding the permissible temperature). According to conservative principles, GHG emissions from the dump burning process are included in the emission reduction calculations in case of re-ignition during project implementation.

Heat and power generation

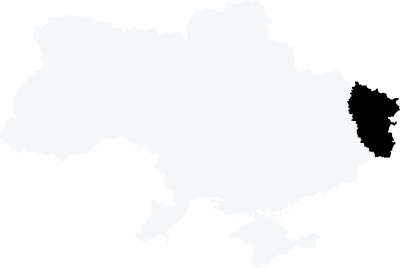

Reconstruction of water supply and drainage system "Luganskvoda Ltd.

The purpose of the project is the modernization and restoration of the system of centralized water supply and sanitation, LTD “Luganskvoda” and also, optimization of the operation of the water supply and sanitation system in terms of its energy efficiency.

Details of events/modernization:

- Refurbishment of pumping equipment, pcs.: 178

- Replacement pumping equipment, pcs: 296

- Installation of new groups of metering devices, pcs: 124

- Installation of automatic air valves, pcs: 58

- Installation of frequency regulators, pcs: 41

- Replacement of water supply networks, km: 69,067

- Optimization of technological process of pumping water, pcs.: 64

- Replacement of energy-intensive pumps with new highly energy-efficient ones;

- Optimization of the technological process of pumping water;

- Introduction of automatic air valves on water pipelines to reduce pressure and improve throughput;

- Replacement of water supply networks;

- Installation of new groups of metering devices;

- Introduction of new devices for hidden leak detection;

- Installation of frequency regulators.

Heat and power generation

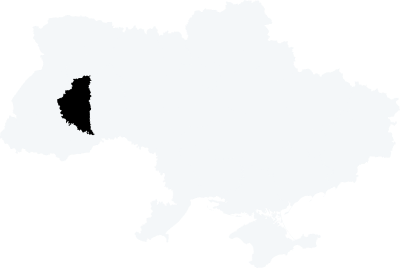

Modernization of the Heat Supply System of Ternopil City

The purpose of the project is to increase the energy efficiency of the heat supply system by replacing old boilers, modernizing boiler equipment and heating systems, with the installation of pre-insulated pipes.

Details of events/modernization:

- Replacement of old boilers with new, more energy efficient ones.

- Modernization of boiler equipment.

- Modernization of heating systems, installation of pre-insulated pipes.

Heat and power generation

Reduction of Greenhouse Gases by Demolition of Waste Heaps of Ltd. “PROMINVEST-EKOLOHIIA”

The purpose of the project is the complete demolition of the dumps of mines No. 20, No. 42, No. 3-14, No. 22 and the Engels mine. As a result of the project implementation, it was planned to eliminate the possibility of spontaneous combustion of waste heaps. This part of the project is unprofitable, so the joint implementation mechanism was one of the critical factors of the project from the very beginning, and the financial benefit under this mechanism was considered one of the reasons for the implementation of the project.

Details of events/modernization:

- Demolition of rock with special equipment, loading onto vehicles and further transportation.

- Direction of demolition products to boiler houses for burning as fuel. Thus, the rock in the dumps is completely utilized, and the resulting coal has replaced the coal that was mined underground.

Heat and power generation

Implementation of Measures on Reduction of Energy Consumption and Greenhouse Gas Emissions at "ICE "Tekhnogaz" LLC

The purpose of the project is to reduce energy consumption and greenhouse gas emissions.

Details of events/modernization:

- Modernization of existing heat generating equipment.

- Modern gas and heat metering devices, heating network management systems, control, management and automation systems for thermal power facilities were used.

- New energy-efficient and energy-saving types of technological equipment have been introduced into the production process.

- Computerization of operations and installation of control and measuring instruments (KIM) with data output to the central screen and to the computer of the production line was carried out.

- The installation of heat exchange equipment for the utilization of heat of the gas-vapor mixture and the utilization of heated water in heating and ventilation systems was carried out.

Heat and power generation

Implementation of 800 MW power generating unit No.2 at Nizhnevartovskaya GRES

The purpose of the project is the introduction of power unit No. 2 with a capacity of 800 MW.

Details of events/modernization:

- An inventory of emissions has been compiled.

- A system for monitoring greenhouse gas emissions was launched and operates , including a system of accounting and reporting; emissions inventories were compiled.

- A number of joint implementation (JI) projects have been prepared for approval by government agencies, some of these projects already have a positive conclusion from international auditors, and foreign investors have been involved in these projects.

- Together with regional electricity producers, the Fund participated in international tenders for the purchase of GHG emissions.

- Information and analytical system “Greenhouse gases” was developed and implemented in a number of regional energy companies.

- In the energy sector, several regulatory and methodological guidelines have been issued and are in force, including the methodology for calculating GHG emissions from thermal power plants.

Heat and power generation

Modernization and Technical Reequipment of PJSC "Donbasenergo" TPP

The purpose of the project is to improve fuel efficiency and reduce greenhouse gas emissions compared to the baseline scenario.

Details of events/modernization:

- Optimization of networks and circulation pumps, blowers and smoke exhausters

- Installation of soft starters.

- Expansion of the working area of the equipment by removing restrictions on the closing of the throttle operation.

- Reduction of load on equipment in idle mode due to the transition to deep throttling.

- Improvement of the overall efficiency of the equipment through the introduction of group pressure control and productivity.

- Reduction of consumption of cooling water.

- Identification of reserves through process analysis.

- Reduction of downtime losses due to advanced diagnostic tools, etc.

Heat and power generation

Modernization and Technical Reequipment of PJSC "Centrenergo" TPP

The purpose of the project is to increase the efficiency of fuel use and reduce the concentration of greenhouse gases compared to the baseline scenario.

Details of events/modernization:

- Optimization of networks and circulation pumps, blowers and smoke exhausters

- Installation of soft starters.

- Expansion of the working area of the equipment by removing restrictions on the closing of the throttle operation.

- Reduction of load on equipment in idle mode due to the transition to deep throttling.

- Improvement the overall efficiency of the equipment through the introduction of group pressure control and productivity.

- Reduction of consumption of cooling water.

- Identification of reserves through process analysis.

- Reduction of downtime losses due to advanced diagnostic tools, etc.

Heat and power generation

Implementation of Energy-Saving Light Sources in the Public, Corporate аnd Private Sectors of Ukraine

The purpose of the project is to distribute LED and CFL both among individuals (households) and legal entities (industrial, commercial, organizational and government bodies). The distribution of project equipment (LED and CFL) is carried out through consumers of electricity of the 2nd category.

Details of events/modernization:

- Distribution of the total number of CFLs, pieces: 5,374,840.

- The project ensured the distribution of LED lamps and CFLs both among individuals (households) and among legal entities (industrial, commercial, organizational and government structures). There was a distribution of project equipment (LED and CFL) among electricity consumers of the 2nd category.

Heat and power generation

Modernization of the Heat Supply System in Mykolaiv Region

The purpose of the project is to modernize the heat supply system by replacing old boilers with new ones, with a complete modernization of boiler equipment. Including modernization of water treatment and installation of metering systems.

Details of events/modernization:

- Replacement of boiler units, pcs.: 20

- Replacement of burners, pcs.: 6.

- Installation of counters, pcs.: 119.

- Replacement of heat supply networks, m: 945.7.

- Modernization of boiler units, pcs.: 2.

- Introduction of flow control modules and weather-dependent boiler control, pcs.: 1.

- Restoration of the lining and laying of insulation.

- Chemical washing and cleaning.

- Modernization of heating systems, installation of pre-insulated pipes.

- Installation of modern gas and heat metering systems.

Heat and power generation

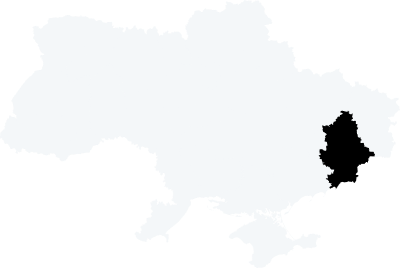

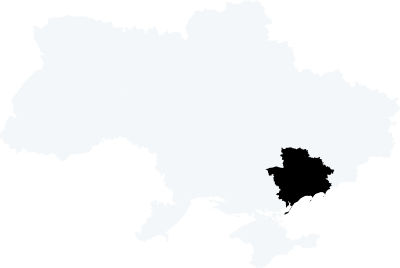

Implementation of the Energy Efficiency Measures and Reduction of Greenhouse Gas Emissions into the Atmosphere at State Enterprise “Snizhneantratsyt”

The purpose of the project is the stabilization of two waste heaps: Dump of the Zarya mine and Dump No. 7 of the Udarnik mine of Snizhneantratsyt, located in Snizhne, Donetsk region.

Details of events/modernization:

- Comprehensive modernization of coal mining equipment and technologies provided for by the comprehensive modernization within the framework of the JI project led to an increase in production efficiency and, as a result, a reduction in energy consumption during coal mining.

- Implementation of dump extinguishing technology at Snizhneantratsyt State Enterprise by isolating hot spots and supplying oxygen to the burning rock. As a result, combustion has ceased, and the possibility of re-ignition is minimized. Implementation of effective monitoring of dumps, a program that provides for monthly monitoring of waste heaps, as well as urgent extinguishing measures in case of an emergency (control points for exceeding the permissible temperature). According to conservative principles, GHG emissions from the dump burning process are included in the emission reduction calculations in case of re-ignition during project implementation.

Heat and power generation

Implementation of the Energy Efficiency Measures and Reduction of Greenhouse Gas Emissions into the Atmosphere at State Enterprise “Selidovugol”

The purpose of the project is a full-scale modernization of the technological equipment involved in the process of coal mining, extinguishing waste heaps of SE Selidovugol. Implementation of a system for stationary monitoring of dumps and technology for extinguishing dumps at the mines of SE Selidovugol.

Details of events/modernization:

- The main activities within the framework of the project “Implementation of measures to improve energy efficiency and reduce greenhouse gas emissions into the atmosphere at SE Selidovugol” were:

- introduction of plate hot water boilers PO 84-15-12-4-2 and dynamic magnetic resonators MGDRMPs-SA;

- installation of a scale protection system on boilers DKVR4/13;

- installation of a soft start system on a 2LU-120 belt conveyor;

- installation of a unified telecommunication system for dispatch control and automatic control of mining equipment and technological complexes (UGOTK);

- improvement of ventilation systems (reduction of air inflow due to pressurization of copra);

- improvement of drainage (cleaning of water collectors and internal surfaces of pipelines, replacement of pumps);

- improvement of underground transport systems (reduction of conveyor time due to the use of pockets);

- Improvement of power supply systems for mines (application of a reactive power compensator KU at a mine transformer substation);

- Improvement of telecommunications for monitoring the energy consumption of systems (adjustment of the Automated Control System for Commercial Power Consumption (ASKUE));

- extinguishing burning heaps;

- setting up a waste heap monitoring system;

- implementation of technology for extinguishing waste heaps in accordance with NPAOP 10.0-5.21-04 Manual on the prevention of spontaneous combustion, extinguishing and demolition of waste heaps using modern antipyrogenic materials;

- modernization and installation of new conveyor equipment;

- acquisition of modern mechanical systems and tunneling machines.

Heat and power generation

Implementation of the Energy Efficiency Measures and Reduction of Greenhouse Gas Emissions into the Atmosphere at State Enterprise “Krasnoarmeyskugol”

The purpose of the project is to extinguish and stabilize dumps No. 1 (Mine Rodynskaya) and No. 3 (Mine Dimitrovskaya), which are under the jurisdiction of SE “Krasnoarmeyskugol”, located in the city of Dimitrov, Rodynsky, Donetsk region. Project activities will reduce greenhouse gas emissions into the atmosphere. The activity of the project is to stabilize the waste heap with the use of vermiculite material.

Details of events/modernization:

- Comprehensive modernization of coal mining equipment and technologies provided for by the comprehensive modernization within the framework of the JI project led to an increase in production efficiency and, as a result, a reduction in energy consumption during coal mining.

- Implementation of technology for extinguishing dumps at the Dimitrovskaya mine SE “Krasnoarmeyskugol” by isolating hot spots and supplying oxygen to the burning rock. As a result, combustion has ceased, and the possibility of re-ignition is minimized. Implementation of effective monitoring of dumps, a program that provides for monthly monitoring of waste heaps, as well as urgent extinguishing measures in case of an emergency (control points for exceeding the permissible temperature). According to conservative principles, GHG emissions from the dump burning process are included in the emission reduction calculations in case of re-ignition during project implementation.

Heat and power generation

Implementation of the Energy Efficiency Measures and Reduction of Greenhouse Gas Emissions into the Atmosphere at State Enterprice “Shakhtarskantratsyt”

The purpose of the project is to extinguish and stabilize the dumps, which are under the jurisdiction of three mines, which are managed by the State Enterprise “Shakhtarskantratsyt”, located in the city of Shakhtersk and Khartsyzsk, Donetsk region. Reducing greenhouse gas emissions into the atmosphere.

Details of events/modernization:

- Comprehensive modernization of coal mining equipment and technologies provided for by the comprehensive modernization within the framework of the JI project led to an increase in production efficiency and, as a result, a reduction in energy consumption during coal mining.

- Implementation of technology for extinguishing dumps at the State Enterprise “SHAKHTARSKANTRATSIT” by isolating hot spots and supplying oxygen to the burning rock. As a result, combustion has ceased, and the possibility of re-ignition is minimized. Implementation of effective monitoring of dumps, a program that provides for monthly monitoring of waste heaps, as well as urgent extinguishing measures in case of an emergency (control points for exceeding the permissible temperature). According to conservative principles, GHG emissions from the dump burning process are included in the emission reduction calculations in case of re-ignition during project implementation.

Heat and power generation

Implementation of the Energy Efficiency Measures and Reduction of Greenhouse Gas Emissions into the Atmosphere at State Enterprise “Artemugol”

The purpose of the project is to increase production efficiency and reduce energy consumption in coal mining. Extinguishing dumps by isolating hot spots and supplying oxygen to the burning rock.

Details of events/modernization:

- Comprehensive modernization of coal mining equipment and technologies provided for by the comprehensive modernization within the framework of the JI project led to an increase in production efficiency and, as a result, a reduction in energy consumption during coal mining.

- Implementation of waste dump extinguishing technology at Artemugol State Enterprise by isolating hot spots and supplying oxygen to the burning rock. As a result, combustion has ceased, and the possibility of re-ignition is minimized. Implementation of effective monitoring of dumps, a program that provides for monthly monitoring of waste heaps, as well as urgent extinguishing measures in case of an emergency (control points for exceeding the permissible temperature). According to conservative principles, GHG emissions from the dump burning process are included in the emission reduction calculations in case of re-ignition during project implementation.

Heat and power generation

Implementation of the Energy Efficiency Measures and Reduction of Greenhouse Gas Emissions into the Atmosphere at State Enterprise “Mine Administration “Pivdennodonbasske No. 1”

The purpose of the project is to introduce measures aimed at improving energy efficiency and reducing greenhouse gas emissions into the atmosphere.

Details of events/modernization:

- Comprehensive modernization of coal mining equipment.

- Implementation of dump extinguishing technology at State Enterprise Pivdennodonbasske No. 1 Mine Administration.

Heat and power generation

Implementation of the Energy Efficiency Measures and Reduction of Greenhouse Gas Emissions into the Atmosphere at SS “Coal mine named after F.E. Dzerzhynskyi”, SE “DZERZHINSKUGOL”

The purpose of the project is to extinguish and stabilize dumps with the use of vermiculite material, which are under the control of the mine “im. F.E. Dzerzhinsky” SE “DZERZHINSKUGOL”, located in the city of Dzerzhinsk, Donetsk region. Reducing greenhouse gas emissions into the atmosphere.

Details of events/modernization:

- The project stabilized dumps belonging to the mine “im. F.E. Dzerzhinsky” SE “DZERZHINSKUGOL”. A high-cost technology using vermiculite material was used to stabilize the dumps.”

Heat and power generation

Implementation of Energy Saving Equipment and Technologies at the State Enterprise "Production Association Yuzhny Machine-Building Plant named after A. Makarov"

The purpose of the project is the introduction of energy-saving equipment and technologies, with the help of which productivity was increased and indicators, energy efficiency, resource efficiency were improved, and the environmental impact on the environment was reduced.

Details of events/modernization:

- Modernization of the main and auxiliary equipment, including:

- reconstruction of HPP with replacement of low-efficiency steam and hot water boilers with modern high-efficiency ones, replacement and reconstruction of boiler units and auxiliary equipment;

- restoration of power generating equipment;

- restoration and replacement of pumping equipment;

- replacement of compressor equipment;

- installation of frequency regulation on drives of draft and pumping equipment.

- Reorganization of the energy supply scheme for technological processes, including:

- ensuring the possibility of stopping and / or reducing the load on the boiler-compressor equipment during breaks in technological processes;

- load disconnection from an inefficient boiler house;

- transfer of steam generating equipment to an electric drive;

- transfer of compressor equipment to an electric drive;

- approaching sources of steam and compressed air production to consumers with the possibility of excluding steam distribution networks and returning condensate;

- concentration of technological equipment to optimize the heated area;

- introduction of automated systems for control and regulation of equipment and accounting for energy resources.

- Reconfiguration of network (pipeline) equipment, including:

- liquidation and/or reduction of leaks of coolant, compressed air, liquefied gases and process water;

- reducing the length of pipelines;

- restoration of pipelines and thermal insulation.

- Installation of new technological equipment to replace the obsolete one, including:

- metalworking machines from the world’s leading manufacturers;

- unique equipment for flash butt welding;

- equipment for applying thermal coatings;

- a unique test chamber for checking the operation of spacecraft.

Heat and power generation

Implementation of Energy Saving Measures at PJSC "Lysychanskiy Glass Factory "Proletary"

The purpose of the project is to modernize the production of PJSC “Lysychanskiy glass factory “Proletary” taking into account the increase in energy efficiency and resource efficiency of the enterprise, as well as the system for monitoring the consumption of energy resources. Implementation of subprojects on “Utilization of waste flue gases”, “Introduction of a modern line for the production of float glass”, “Modernization of the existing production of float glass”.

Details of events/modernization:

- In accordance with the implementation schedule, the following operating power facilities were reconstructed:

- firebox walls made of highly fire-resistant materials were installed;

- increased filling volumes of regenerators;

- new designs of burners were installed with the expansion of the port route;

- increased insulation of the bottom and walls and reduced the depth of the pool;

- installed ASKUE (automated system for commercial metering of electricity consumption) with modern high-accuracy meters for differential metering, transmission and storage of information about electricity;

- installed frequency converters in blow fans of glass melting furnace No. 3, allowing to adjust the performance (addition) of the fan.

- “Subproject No. 1” was implemented. Utilization of flue gases. The utilization of flue gases generates heat that, in the absence of project measures, would use fossil fuels (natural gas).

- “Subproject No. 2” was implemented. Implementation of a modern line for the production of float glass. The measures provide for a reduction in the consumption of electricity and natural gas through the introduction of a modern technological line with a lower consumption of energy resources. Reducing the consumption of electricity in the production process will reduce the consumption of fossil fuels for electricity generation in the grid, and reducing the consumption of natural gas will also reduce GHG emissions.

- “Subproject No. 3 was implemented. Modernization of the existing production of float glass. The subproject provides for a reduction in specific power and consumption of natural gas due to the reconstruction of existing facilities: the use of modern models of burners, changing the geometry of the furnace, the use of frequency controllers on the electrical equipment of shops and the introduction of electric heating of shops. glass melts. The reduction in specific consumption will lead to a reduction in electricity consumption and the use of natural gas, which will lead to a reduction in greenhouse gas emissions. In addition, the project will provide additional benefits, such as economic efficiency, labor protection and an incentive for the implementation of similar projects in other industrial enterprises in Ukraine.

Heat and power generation

Rehabilitation of the District Heating System in Dnipropetrovsk Region

The purpose of the project is the modernization of the district heating system, including the replacement of burners and boiler automation. Using the potential of waste heat from flue gases, as well as reconstructing the heating network system and installing frequency controllers on pump motors for pumping water as a heat carrier. Creation of a monitoring and control system for the heat supply system in the Dnepropetrovsk region at PJSC “Oblteplokommunenergo”.

Details of events/modernization:

- Replacement of outdated low efficiency boilers with new high efficiency boilers.

- Boiler equipment restored.

- Replacement of inefficient burners.

- Installation of heat recovery units.

- The length of pipelines has been reduced with the replacement of 4-pipe lines with 2-pipe lines using new insulation and pre-insulated pipes.

- Quarterly gas-fired boiler houses were built on the basis of existing central heating points (CHPs).

- Technical re-equipment of the central heating station, heat exchangers.

- Installation of frequency controllers on electric drives of smoke exhausters.

- Installation of modern heat metering devices, monitoring systems for heating networks and implemented control, management and automation of heat generating facilities.

- A system for monitoring and energy audit of energy system facilities has been created.

Heat and power generation

Rehabilitation of the District Heating System of Zaporizhzhia City

The purpose of the project is the modernization of the district heating system, including the replacement of burners and boiler automation and switching to alternative fuels. Using the potential of waste heat from flue gases, as well as reconstructing the heating network system and installing frequency controllers on pump motors for pumping water as a heat carrier.

Details of events/modernization:

- Replacement of old boilers with new high-efficiency boilers;

- Installation of heat recovery units;

- Restoration of central heating points (CHP)

- Installation of individual heat supply points (ITHS)

- Rehabilitation of heat supply networks using pre-insulated pipes;

- Installation of cogeneration plants;

- Installation of frequency regulators at boiler houses and central heating stations;

- Transfer of boiler houses from natural gas to biofuel;

- Construction of a heat pump station TsVS No. 1 to use wastewater heat;

- Use of waste thermal energy from secondary energy sources (SER) of industrial enterprises.

Heat and power generation

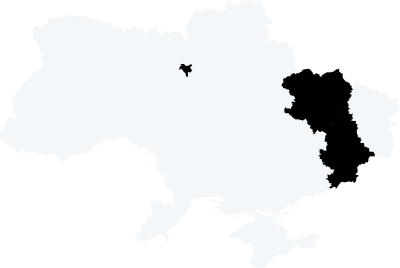

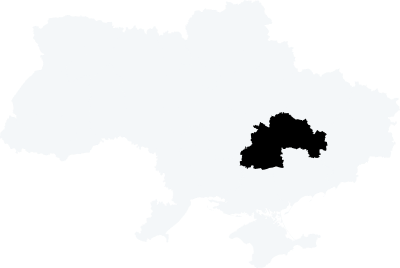

Rehabilitation of the District Heating System in Donetsk City

The purpose of the project is to modernize the district heating system, including the replacement of burners and boiler automation, taking into account the transfer of load from boiler houses with outdated equipment to boiler houses with high-efficiency equipment. Using the potential of waste heat from flue gases, as well as the reconstruction of the heating network system and the installation of frequency controllers on the motors of hot water pumps.

Details of events/modernization:

- Reconstruction of the heat network system made it possible to reduce the loss of heat energy to 1-2% per 1 km by replacing the pipes of the main and distribution networks with a diameter of 48-630 mm using pre-insulated pipes.

- Reconstruction of boilers with the replacement of burners and automation.

- Switching the load from boiler houses with outdated equipment to boiler houses with high efficiency equipment.

- Utilization and recovery of exhaust gas heat with the help of installed contact and surface heat recovery gas cleaning devices (utilizers), including developments of the Institute of Engineering Ecology.

- Utilization of the additional heat of steam condensation, which occurs when the exhaust gas temperature drops below the dew point, was carried out. The introduction of this technology has increased the efficiency of fuel consumption by 6-8%.

- Installation of frequency controllers on hot water pump motors resulted in energy savings.

Heat and power generation

Implementation of the Energy Efficiency Measures at SE "Malyshev Plant"

The purpose of the project is the introduction and use of more efficient production technologies and equipment at the Malyshev Plant State Enterprise. As a result, the project has improved energy efficiency and energy use, resulting in lower greenhouse gas (GHG) emissions compared to current practice.

Details of events/modernization:

- New efficient energy-saving technological equipment was installed for the production of cast iron, steel, non-ferrous metals and other products, which are accounted for in tons.

- Metering devices were replaced.

- Heat generating equipment was replaced, such as:

- gas and electric boilers;

- stoves;

- drying equipment;

- heaters.

- Technological and auxiliary equipment has been replaced:

- electric furnace IAT 2.5/1.6 H3;

- casting machine 659a;

- mine electric furnace SSH3-6.30/742;

- Analytical system for quality control of endogas AS-KhTs-A;

- end-grinding machine ВТ3Т153Е;

- hydraulic machine OM-9969-190M;

- AKP 9973-5394 Installation for loading induction heating

- Analytical system for quality control of endogas AS-KhTs-A;

- 9969-5189 installation for molding and deformation of blanks;

- injection molding machine 711-A08-CM;

- injection molding machine 9969-5114;

- 9973-024 water charger; rotating device 72/22;

- shake the table;

- casting machine 9-5903;

- electric furnace SSHTSM 6.6/9;

- electric furnace CH3-8 16.5/1042; hardening furnace;

- electric furnace СШО-6.3/1041;

- contact welding machine KSh 002 UHL4;

- contact welding machine KSh 001 UHL 4;

- band saw machine SLP-8530;

- A-1416 submerged arc welding machine with a KIU rectifier;

- continuous mixer S1SH-3А;

- semiautomatic device for surfacing PDKHO-602 with VDU-601; internal grinding machine UVA-13;

- balancing machine VM-050;

- internal grinding machine UVA-13;

- universal cylindrical grinding machine with S 21;

- Studer system;

- preservative bath ADR 9986-7239;

- Electrogrinding bath ADR 9986-8396;

- ADR 9955-6474 stand for pressing;

- circular grinding machine 3M174;

- molding machine 64111;

- 52-655 automated installation;

- 61701 automatic machine for the preparation of molding masses;

- Endogas plant EN-125;

- automated line for the formation and firing of blanks;

- Plasmorez A-1612.

Heat and power generation

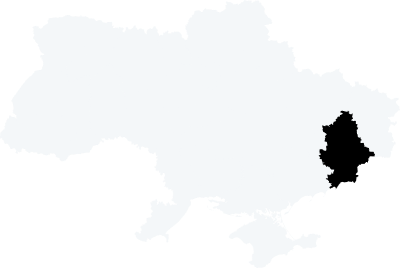

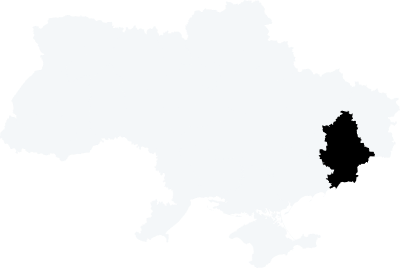

Implementation of the Energy Efficiency Measures and Reduction of Greenhouse GasEmissions into the Atmosphere at State Enterprice “Coal Company “Krasnolimanska”

Heat and power generation

The purpose of the project is to increase production efficiency and reduce energy consumption

in coal mining. And also, extinguishing dumps by isolating hot spots and supplying oxygen to the burning

rock. Implementation of coal mine methane (CMM) extraction technology.

Details of events/modernization:

- Comprehensive modernization of coal mining equipment and technologies provided for by

the comprehensive modernization within the framework of the JI project led to an increase in

production efficiency and, as a result, a reduction in energy consumption during coal mining. - Implementation of the technology for extinguishing waste heap No. 2 at the State Enterprise

Krasnolimanska CC by isolating hot spots and supplying oxygen to the burning rock. As a result,

combustion has ceased, and the possibility of re-ignition is minimized. Implementation of effective

monitoring of dumps, a program that provides for monthly monitoring of waste heaps, as well as urgent

extinguishing measures in case of an emergency (control points for exceeding the permissible

temperature). According to conservative principles, GHG emissions from the dump burning process are

included in the emission reduction calculations in case of re-ignition during project implementation. - Implementation of coal mine methane (CMM) extraction technology.

Heat and power generation

Utilization of Coal Mine Methane at the Coal Mine named after A.F. Zasyadko

Goal of Project

The purpose of the project is to develop, in accordance with the provisions of the

Comprehensive Program, at the section of the Zasyadko mine, its own degassing project, which provides for the drilling of underground wells, the introduction of vacuum pumping stations (VPS) at three production sites: Vostochnaya, Yakovlevskaya and Grigorievskaya.

Details of events/modernization:

- Installing a PowerLink GXE250-NG Gas Engine.

- Drilling and operation 11 drilling rigs are in operation.

- Laid 42 km of degassing pipelines F 630 mm and 530 mm.

- During the implementation of the project, 10-12 km of underground degassing wells were drilled monthly

- 3 vacuum pumping stations were put into operation: two at the Vostochnaya production site, each with 6 vacuum pumps (12 in total) and one at the Yakovlevskaya production site with 9 vacuum pumps.

- Daily flow rate of captured methane – 150 m3/min.

- The development of degassing activities provided for an increase in the rate of captured methane up to 500 m3/min.

- Commissioning of one vacuum pumping station at the Grigorievskaya production site, consisting of 9 vacuum pumps with a capacity of 150 m3/min each.