#3

TOTAL VERIFIED CUTS IN THIS SECTOR AMOUNTS TO – 104 898 228 t CO2

Natural gas production and transmission

Natural gas production and transmission

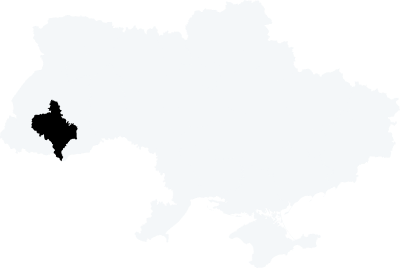

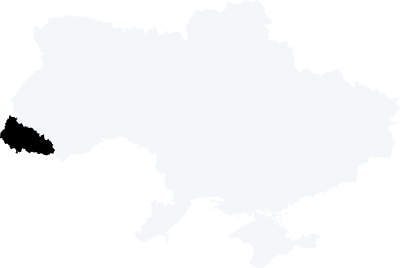

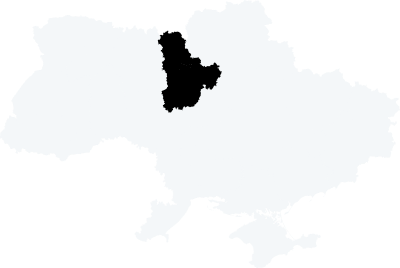

Reduction of Natural Gas Leaks at the Gas Distribution Networks of PJSC “Ternopilgaz”

The purpose of the project is to replace old gas equipment and gas fittings with new units. Replacement of sealing elements with the use of modern sealing materials, change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of hydraulic distribution stations where gas equipment was repaired (replaced), pcs.: 586.

- Number of repaired (replaced) gas fittings in gas distribution networks, pcs.: 1855.

- The implementation of the modernization schedule consisted of the following stages:

- compilation of a primary register of equipment included in the project boundaries (GDP)

gas equipment, gas fittings, threaded and flanged connections of gas pipelines). Inspection;

- gas equipment of the GDP, gas fittings, threaded and flanged connections of gas pipelines and primary control measurements. Signing of a Memorandum of Understanding regarding;

- joint implementation project. Creation of the Working Group. Development of monitoring;

- plan, project PDD, version 01 (January-March 2005);

- introduction and implementation of the PETM program, repair (replacement) of gas;

- equipment, pcs.: 146 hydraulic fracturing and 463 pcs. fittings (February – December 2005);

- implementation of the PETM program, repair (replacement) of gas equipment, pieces: 366 and 1159 gas fittings (January – December 2006);

- implementation of the PETM program, repair (replacement) of gas equipment, pcs: 367;

and 1159 gas fittings (January – December 2007);

- Implementation of the PETM program, repair (replacement) of gas equipment: 219 GDP;

- (UKG) and 696 gas fittings (January – December 2008);

- Implementation of the PETM program, repair (replacement) of gas equipment, units: 367 and 1159 gas fittings (January – December 2009);

- Continued implementation of the PETM program, implementation of regular monitoring;

- inspections and measurements on already repaired hydraulic fracturing equipment and fittings;

- gas pipelines, elimination of leaks on already repaired equipment, if such leaks occur (January 2010 – December 2017).

Natural gas production and transmission

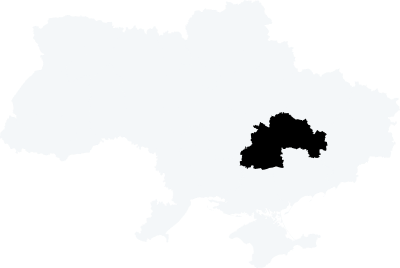

Reduction of Methane Leaks on the Gas Equipment of the Gas Distribution Points and on the Gas Armature, Flanged, Threaded Joints of the Gas Distribution Pipelines of PJSC “Krivorijgaz”

The purpose of the project is to replace old gas equipment and gas fittings with new units. Replacement of sealing elements with the use of modern sealing materials, change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of hydraulic fracturing units with repaired (replaced) gas equipment, pcs.: 169.

- Number of repaired (replaced) units of gas fittings of HDN, pcs.: 1125.

Natural gas production and transmission

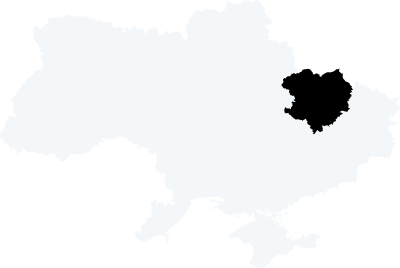

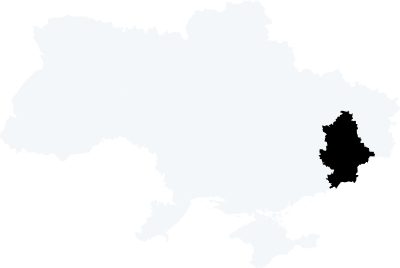

Reduction of Methane Leaks on the Gas Equipment of the Gas Distribution Points and on the Gas Armature, Flanged, Threaded Joints of the Gas Distribution Pipelines of PJSC “Kharkivmiskgaz”

The purpose of the project is to replace old gas equipment and gas fittings with new units. Replacement of sealing elements with the use of modern sealing materials, change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of hydraulic fracturing units with repaired (replaced) gas equipment, pcs.: 1230.

- Number of repaired (replaced) units of gas fittings of HDN, pcs.: 63,327.

Natural gas production and transmission

Reduction of Methane Leaks on the Gas Equipment of the Gas Distribution Points and on the Gas Armature, Flanged, Threaded Joints of the Gas Distribution Pipelines of PJSC “Kharkivgaz”

The purpose of the project is to replace old gas equipment and gas fittings with new units. Replacement of sealing elements with the use of modern sealing materials, change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of hydraulic fracturing units with repaired (replaced) gas equipment, pcs.: 1708.

- Number of repaired (replaced) units of gas fittings of HDN, pcs.: 3751.

Natural gas production and transmission

Reduction of Methane Leaks on the Gas Equipment of the Gas Distribution Points and on the Gas Armature, Flanged, Threaded Joints of the Gas Distribution Pipelines of PJSC “Dniprogaz”

The purpose of the project is to replace old gas equipment and gas fittings with new units. Replacement of sealing elements with the use of modern sealing materials, change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of hydraulic fracturing units with repaired (replaced) gas equipment, pcs.: 1676.

- Number of repaired (replaced) units of gas fittings of HDN, pcs.: 2974.

Natural gas production and transmission

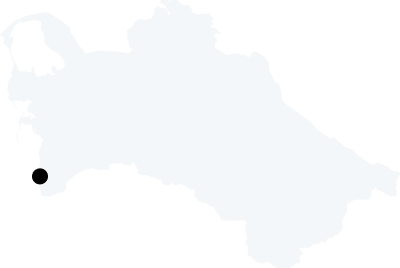

Utilization of associated petroleum gas at the “Keymir” oil and gas condensate field

The purpose of the project is the processing, transportation and utilization of flared gas.

Details of events/modernization:

- installation of a compressor station (CS) at the Keymir field. The CS is designed for utilization of associated petroleum gas (APG) from Keymir and Akpatlavuk fields and supply thereof to the Turkmenistan-Iran export pipeline;

- handling the entire amount of gas, which is usually flared, and, as a consequence, reducing GHG emissions through utilization of APG from the Keymir and Akpatlavuk fields instead of natural gas.

Natural gas production and transmission

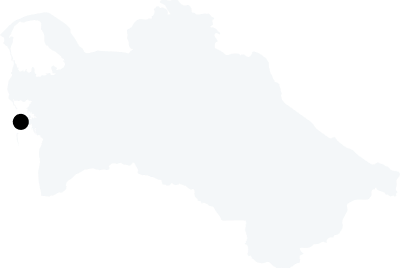

Utilization of associated petroleum gas at the “Khazar” oil and gas condensate field

The purpose of the project is the processing, transportation and utilization of flared gas.

Details of events/modernization:

- installation of a Boosting Compressor Station (BCS) at the Khazar field (Chekelen). The BCS is designed for utilization of associated petroleum gas (APG) from offshore fields. The gas will be supplied via Khazar-Goturdepe gas pipeline to the Goturdepe compressor station and to the SATs-III pipeline;

- utilizing the entire amount of gas, which is usually flared, and, as a consequence, of reducing GHG emissions through utilization of APG from the Khazar field (Chekelen) instead of natural gas.

Natural gas production and transmission

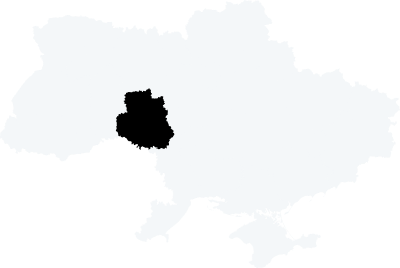

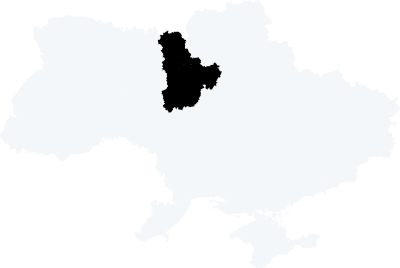

Reduction of Greenhouse Gases Emissions by Gasification of Ivano-Frankivsk Region

The purpose of the project is the construction of new and expansion of existing gas distribution systems (GDS), consisting of organizationally and technologically related facilities designed to transport natural gas directly from gas pipelines to individual consumers. In addition, it is planned to use a flexible gas hose and install cathodic protection units.

Details of events/modernization:

- The project included the implementation of the following stages:

- Construction of the GDS:

а. use of steel welded pipes of medium and low pressure;

- use of medium and low pressure polyethylene pipes;

- installation of means of protection against electrical and chemical corrosion;

- installation of other elements of the GDS;

- measurement and control of gas fittings;

- Shut-off and regulating gas fittings.

- The project implemented the construction of new and expansion of existing gas distribution systems (GDS), consisting of organizationally and technologically related facilities designed to transport natural gas directly from the main gas pipelines to individual consumers.

- The use of a flexible gas hose is applied.

- The setting of cathodic protection settings has been applied.

- Implementation of maintenance of the specified load current when the mains voltage changes within 170V – 250V interruption of the load current.

- Implementation of automatic maintenance of a given protective potential.

- Registration of the time of the presence of a given potential at the object that is being guarded has been implemented.

- Implementation of protection against overloads and short circuits in the load circuit.

- Implementation of shutdown of the unit when the supply voltage drops below 170V with automatic switching to the operating mode when the voltage rises.

- Implementation of automatic transition to the operating mode after the complete disappearance and subsequent appearance of the supply voltage.

Natural gas production and transmission

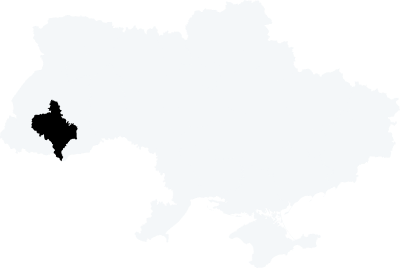

Reduction of Methane Leaks on the Gas Equipment of the Gas Distribution Points and on the Gas Armature, Flanged, Threaded Joints of the Gas Distribution Pipelines of PJSC “Ivano-Frankivskgas”

The purpose of the project is to replace old gas equipment and gas fittings with new units. Replacement of sealing elements with the use of modern sealing materials, change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of hydraulic fracturing units with repaired (replaced) gas equipment, pcs.: 2436.

- Number of repaired (replaced) units of gas fittings of HDN, pcs.: 2631.

Natural gas production and transmission

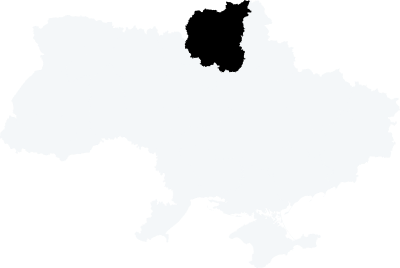

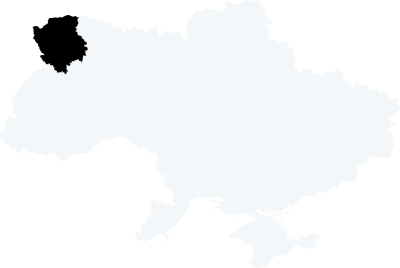

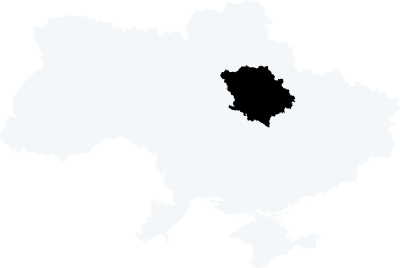

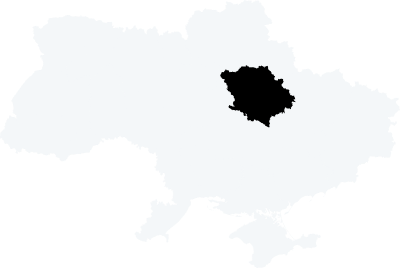

Reduction of Methane Leaks on the Gas Equipment of the Gas Distribution Points and on the Gas Armature, Flanged, Threaded Joints of the Gas Distribution Pipelines of PJSC “Chernigivgas”

The purpose of the project is to reduce losses during the transportation of natural gas (methane) through the complete replacement of old gas equipment and gas fittings with new units. And also, the replacement of sealing elements using modern sealing materials, a change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of hydraulic distribution stations where gas equipment was repaired (replaced), pcs.: 966.

- Number of repaired (replaced) gas fittings in gas distribution networks, pcs.: 1987.

Natural gas production and transmission

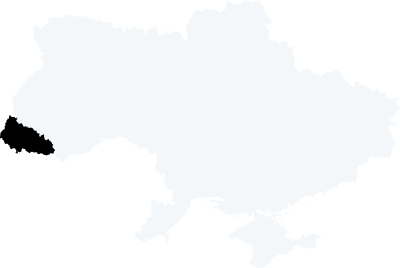

Reduction of Greenhouse Gases Emissions by Gasification of Zakarpattia Region

The purpose of the project is the construction of new and expansion of existing gas distribution systems (GDS), consisting of organizationally and technologically related facilities designed to transport natural gas directly from gas pipelines to individual consumers. In addition, it is planned to use a flexible gas hose and install cathodic protection units.

Details of events/modernization:

- The project included the implementation of the following stages:

GDN construction:

- а. use of steel welded pipes of medium and low pressure;

- use of medium and low pressure polyethylene pipes;

- installation of means of protection against electrical and chemical corrosion;

- installation of other elements of the GDS;

- measurement and control of gas fittings;

- Shut-off and regulating gas fittings.

- The project implemented the construction of new and expansion of existing gas distribution systems (GDS), consisting of organizationally and technologically related facilities designed to transport natural gas directly from main gas pipelines to individual consumers.

- The use of a flexible gas hose is applied.

- The setting of cathodic protection settings has been applied.

- Implementation of maintenance of the specified load current when the mains voltage changes within 170V – 250V interruption of the load current.

- Implementation of automatic maintenance of a given protective potential.

- Registration of the time of the presence of a given potential at the object that is being guarded has been implemented.

- Implementation of protection against overloads and short circuits in the load circuit.

- Implementation of shutdown of the unit when the supply voltage drops below 170V with automatic switching to the operating mode when the voltage rises.

- Implementation of automatic transition to the operating mode after the complete disappearance and subsequent appearance of the supply voltage.

Natural gas production and transmission

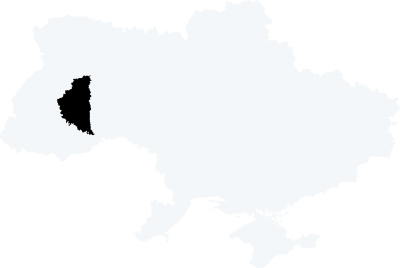

Reduction of Methane Leaks on the Gas Equipment of the Gas Distribution Points and on the Gas Armature, Flanged, Threaded Joints of the Gas Distribution Pipelines of PJSC “Zakarpatgas”

The purpose of the project is to reduce losses during the transportation of natural gas (methane) through the complete replacement of old gas equipment and gas fittings with new units. And also, the replacement of sealing elements using modern sealing materials, a change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of gas distribution units (GRPs) where gas equipment was repaired (replaced), pcs.: 885.

- Number of repaired (replaced) gas fittings in gas distribution networks, pcs.: 1625.

Natural gas production and transmission

Reduction of Greenhouse Gases Emissions by Gasification of Volyn Region

The purpose of the project is the construction of new and expansion of existing gas distribution systems (GDS), consisting of organizationally and technologically related facilities designed to transport natural gas directly from gas pipelines to individual consumers. In addition, it is planned to use a flexible gas hose and install cathodic protection units.

Details of events/modernization:

- Gas distribution networks built, km: 1.2965333.

- The use of a flexible gas hose is applied.

- The setting of cathodic protection settings has been applied.

- Implementation of maintenance of the specified load current when the mains voltage changes within 170V – 250V interruption of the load current.

- Implementation of automatic maintenance of a given protective potential.

- Registration of the time of the presence of a given potential at the object that is being guarded has been implemented.

- Implementation of protection against overloads and short circuits in the load circuit.

- Implementation of shutdown of the unit when the supply voltage drops below 170V with automatic switching to the operating mode when the voltage rises.

- Implementation of automatic transition to the operating mode after the complete disappearance and subsequent appearance of the supply voltage.

Natural gas production and transmission

Reduction of Methane Leaks on the Gas Equipment of the Gas Distribution Points and on the Gas Armature, Flanged, Threaded Joints of the Gas Distribution Pipelines of PJSC “Volyngas”

The purpose of the project is to reduce losses during the transportation of natural gas (methane) through the complete replacement of old gas equipment and gas fittings with new units. And also, the replacement of sealing elements using modern sealing materials, a change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of hydraulic distribution stations where gas equipment was repaired (replaced), pcs.: 1130.

- Quantity of repaired (replaced) gas fittings GRN, pcs.: 1507.

Natural gas production and transmission

Reduction of Direct Methane Emissions by Implementation of Innovative Repair Methods at Technological Equipment of Public Joint Stock Company "National Joint Stock Company "Chornomornaftogaz"

The purpose of the project is to introduce innovative repair methods that allow repairing gas pipelines with identified defects through the use of detachable couplings and rings between the repaired gas pipeline and the coupling and the further introduction of a special self-pressurizing hardening compound (sealant) in the space formed between the outer surface of the pipeline and the inner surface of the sleeve.

Details of events/modernization:

- Number of repairs: 160.

Natural gas production and transmission

Reduction of Greenhouse Gases Emissions by Gasification of Vinnitsya Region

The purpose of the project is gasification of end consumers through the construction and reconstruction of gas distribution networks and avoiding heating with solid and liquid fuels.

Details of events/modernization:

- Length of gas distribution networks implemented under the project: 383.26 km.

- Ensuring the supply of natural gas (gasification) to end consumers through the construction and reconstruction of gas distribution networks.

- Replacement of solid and liquid fuels with natural gas.

- Increasing the efficiency of thermal energy use.

Natural gas production and transmission

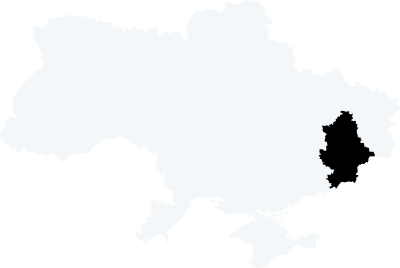

Reduction of Greenhouse Gases Emissions by Gasification of Mariupol City

The purpose of the project is to reduce greenhouse gas emissions by changing the structure of fuel consumption in the industrial, municipal, administrative and private sectors of the city of Mariupol by replacing solid and liquid fuels with natural gas. The project provided for the construction and expansion of gas distribution systems (GDS) in Mariupol, which also made it possible to increase the energy efficiency of thermal generation by switching existing heat supply systems to natural gas. The result of the project, initiated by PJSC “Mariupolgaz”, was the reduction of greenhouse gas emissions into the atmosphere and the improvement of the environmental situation in the region.

Details of events/modernization:

- Installation of gas meters, pcs.: more than 5000

- Installation of individual gas equipment, pcs.: 5000

- Construction of gas distribution networks (GDS): 136.293 km

- Ensuring the supply of natural gas (gasification) to end consumers through the construction and reconstruction of gas distribution networks.

- Replacement of solid and liquid fuels with natural gas.

- Increasing the efficiency of thermal energy use.

Natural gas production and transmission

Reduction of Greenhouse Gases Emissions by Gasification of Kyiv City

The purpose of the project is to switch to more environmentally friendly fuel by modernizing the power supply system in Kyiv. As a result of the project implementation, fuel efficiency has been improved and greenhouse gas emissions have been reduced compared to current practice. The project was initiated by PJSC “Kyivgaz” to improve the environmental situation in the region.

Details of events/modernization:

- Installation of gas meters, pcs.: 20000.

- Installation of individual gas equipment, pcs.: 12000.

- Gas distribution networks built, km: 35.82.

- Ensuring the supply of gaseous fuel (gasification) to end consumers through the construction and reconstruction of the gas distribution network.

- Replacement of solid and liquid fuels and electricity with natural gas.

- Increasing the efficiency of thermal energy use.

Natural gas production and transmission

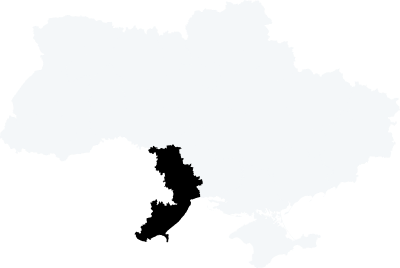

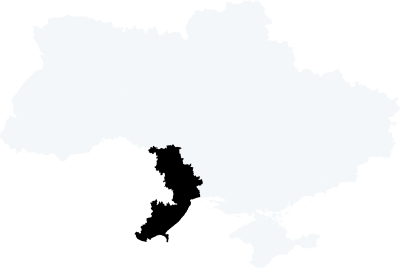

Reduction of Greenhouse Gases Emissions by Gasification of Odesa Region

The purpose of the project is to reduce greenhouse gas emissions by changing the structure of fuel consumption in the industrial, municipal, administrative and private sectors of the Odessa region by replacing solid and liquid fuels with natural gas. The project provided for the construction and expansion of gas distribution systems (GDS) in Odessa region, which also made it possible to increase the energy efficiency of thermal generation by switching existing thermal power plants to natural gas, installing individual heating and hot water supply.

Details of events/modernization:

- Construction of a new system for the delivery of energy to the settlements of the Odessa region – gas pipelines over 4000 km.

- Built gas control points, cabinet gas control points, pcs: 234

- Installed gas meters, pcs.: 14,835.

- Installation of gas equipment (TS, IK (individual boilers) – more than 60,000 points.

- Replacement of solid (coal) and liquid (fuel oil, furnace) fuels with natural gas.

Natural gas production and transmission

Reduction of Natural Gas Leaks at the Gas Distribution Networks of PJSC “Ternopilmiskgaz”

Goal of Project

The goal of the project is to reduce natural gas leaks in the gas transmission and distribution infrastructure of PJSC Odesagas. The main sources of leaks are switch mechanisms (bolts, taps, fittings), flanged and threaded connections of gas pipelines of PJSC Odesagas in the amount of 11,174 pcs., GDP and SRRP in quantity The main reason for the leakage of natural gas is the rapid failure of the sealing elements. The elimination of the methane leak led to a reduction in greenhouse gas emissions.

Details of events/modernization:

- Replacement of points – 11,174 gas fittings in distribution networks.

- Replacement, pcs. – 1,851 GСP and СGCP.

- Implementation of a targeted inspection and maintenance of gas distribution points and cabinet gas distribution points, purchased and calibrated new modern measuring equipment, appropriate employee training, developed monitoring maps with a list of all equipment components subject to regular inspection, creation of a system for collecting and storing data on leaks, and an internal audit and quality system has also been introduced. to eliminate and account for methane leaks.

Natural gas production and transmission

Reduction of Methane Emissions on the Gas Equipment of Gas Distribution Points, Gas Armature, Flanged and Threaded Joints of Gas Distribution Networks of PJSC "Poltavagaz"

The purpose of the project is the complete replacement of obsolete and obsolete gas equipment and gas fittings with new units. Carrying out repairs of units of gas equipment and gas fittings. Replacing sealing elements with the use of modern sealing materials, changing the practice of maintenance and repair, which has become generally accepted, based on paronite gaskets, as well as sealing packing made of cotton fibers impregnated with grease and asbestos-graphite filler.

Details of events/modernization:

- Number of repaired GDPs/GTPs, pcs.: 249.

- Number of repaired (replaced) gas appliances of gas distribution networks, pcs.: 506.

- Complete replacement of obsolete and obsolete gas equipment and gas fittings with new units.

- Repair of units of gas equipment and gas fittings.

- Replacing sealing elements with the use of modern sealing materials, changing the practice of maintenance and repair, which has become generally accepted, based on paronite gaskets, as well as sealing packing made of cotton fibers impregnated with grease and asbestos-graphite filler.

Natural gas production and transmission

Reduction of Methane Emissions on the Gas Equipment of Gas-distributing Points and on the Gas Armature of Gas-distributing Networks of CJSC “Theodosia”

The purpose of the project is the complete replacement of obsolete and obsolete gas equipment and gas fittings with new units. Carrying out repairs of units of gas equipment and gas fittings. Replacing sealing elements with the use of modern sealing materials, changing the practice of maintenance and repair, which has become generally accepted, based on paronite gaskets, as well as sealing packing made of cotton fibers impregnated with grease and asbestos-graphite filler.

Details of events/modernization:

- Repair of GDPs / GTPs (reconstruction, sealing, replacement of gas equipment), pcs.: 63.

- Repair (replacement) of gas fittings, flanges, threaded connections of gas distribution networks, pcs.: 192.

Natural gas production and transmission

Reduction of Natural Gas Leaks at the Gas Distribution Networks of PJSC “Sevastopolgaz”

The purpose of the project is to reduce losses during the transportation of natural gas (methane) through the complete replacement of old gas equipment and gas fittings with new units. And also, the replacement of sealing elements using modern sealing materials, a change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of hydraulic distribution stations where gas equipment was repaired (replaced), pcs.: 28.

- Number of repaired (replaced) gas fittings in gas distribution networks, pcs.: 1155.

Natural gas production and transmission

Reduction of Methane Emissions on the Gas Equipment of Gas Distribution Points and on the Gas Armature, Flanged, Threaded Joints of Gas Distribution Pipelines of PJSC “Lubnygaz”

The purpose of the project is to reduce losses during the transportation of natural gas (methane) through the complete replacement of old gas equipment and gas fittings with new units. And also, the replacement of sealing elements using modern sealing materials, a change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with fat treatment and asbestos-graphite filler.

Details of events/modernization:

- Number of hydraulic distribution stations/GTP where gas equipment was repaired (replaced), pcs: 284.

- Number of repaired (replaced) gas fittings: 1163.

- Complete replacement of old gas equipment and gas fittings with new units.

- Replacement of sealing elements with the use of modern sealing materials, change in the generally accepted practice of maintenance and repair based on paronite packing and gaskets made of cotton fiber with grease treatment and asbestos-graphite filler.

Natural gas production and transmission

Methane Leaks Reduction and Implementation of Energy Efficiency Measures at Technological Equipment of Public Joint Stock Company “National Joint Stock Company “Chornomornaftogaz”

The purpose of the project is to create a system for collecting and storing data on leak volumes, as well as to introduce an internal audit and a system for ensuring the quality of repairs and measuring methane leaks.

Leak Detection and Measurement: The leak monitoring system, including repaired leaks (repaired equipment components), will be carried out on a regular basis by specially trained personnel. Each component will be checked according to the monitoring chart, and the detected leaks will be marked with individual numbers accordingly, the volumes of gas leaks will be measured and recorded in the database.

Repair of all detected leaks: repair of gas transmission system leak joints under this project will range from replacement of gaskets and wedge valves, use of new stuffing box or sealing materials to overhaul and replacement of safety pressure control valves, piston rods, installation of upgraded natural gas meters accuracy. The repaired components of the gas transmission system will be regularly checked as part of a routine monitoring program to ensure that they do not again become a source of leakage. To achieve these goals, the following measures will be applied, which are divided into two groups:

– measures to measure and control leaks;

– measures to eliminate the leak.

Details of events/modernization:

- A system for collecting and storing data on leak volumes has been created, as well as the introduction of an internal audit and a system for ensuring the quality of repairs and measuring methane leaks.

- Leaks detected and measured: Leak monitoring system, including repaired leaks (repaired equipment components), will be carried out on a regular basis by specially trained personnel. Each component will be checked according to the monitoring map, and the leaks found will be marked with individual numbers accordingly, the volumes of gas leaks will be measured and registered in the database.

- Repair of all detected leaks: repair of joints of elements of the gas transmission system with leakage within the framework of this project will vary from the replacement of gaskets and wedge valves, the use of new glands or sealing materials to overhaul and replacement of safety pressure control valves, piston rods, installation of natural gas meters high class of accuracy. The repaired components of the gas transmission system will be regularly checked as part of a routine monitoring program to ensure that they do not again become a source of leakage. To achieve these goals, the following measures will be applied, which are divided into two groups:

- measures to measure and control leaks;

- measures to eliminate the leak.

Natural gas production and transmission

Reduction of Methane Emissions on the Gas Equipment of Gas Distribution Plants, Gas Armature, Flanged and Threaded Connections of Gas Distribution Networks of PJSC "Vinnitsagaz"

The purpose of the project is the complete replacement of obsolete and obsolete gas equipment and gas fittings with new units. Carrying out repairs of units of gas equipment and gas fittings. Replacing sealing elements with the use of modern sealing materials, changing the practice of maintenance and repair, which has become generally accepted, based on paronite gaskets, as well as sealing packing made of cotton fibers impregnated with grease and asbestos-graphite filler.

Details of events/modernization:

- Repair of GDPs / GTPs (reconstruction, sealing, replacement of gas equipment), pcs.: 789.

- Repair (replacement) of gas fittings, flanges, threaded connections of gas distribution networks, pcs.: 101.

Natural gas production and transmission

Reduction of Methane Leakage at Flanged, Threaded Joints and shut-down Devices of the Equipment of OJSC "Kyivgas"

The purpse of the project is to reduce natural gas leaks in the gas distribution infrastructure of OJSC Kyivgaz. The main sources of leaks are switch mechanisms (latches, taps, gates), flanged and threaded connections of gas pipelines of OJSC “Kyivgaz”. The main reason for the leakage of natural gas was the rapid failure of the sealing elements. The elimination of the methane leak led to a reduction in greenhouse gas emissions.

Details of events/modernization:

- As part of the project, ground and underground fittings were replaced in the amount of: 60,613 pcs.

- The introduction of targeted inspection and maintenance of gas distribution points and cabinet gas distribution points is a modern and most cost-effective practice, which made it possible not only to identify leaks, but also to determine the amount of leakage (i.e., the potential volume of gas losses). This activity included the purchase and calibration of modern measuring equipment, the appropriate training of employees, the development of a monitoring card listing all equipment components subject to regular inspection, the establishment of a system for collecting and storing data on leaks, as well as the implementation of an internal audit and quality system to eliminate and record leaks. methane.

- Leak detection and measurement: The leak monitoring system, including repaired leaks (repaired equipment items) was carried out on a regular basis (every four days or once a week, depending on the type of equipment) by specially trained personnel. Each component was checked against a monitoring chart and any leaks found were duly marked with a unique number; gas leakage volumes were measured and recorded in a database.

- Elimination of all identified leaks: repair of leaky joints of hydraulic fracturing and SHHF elements within the framework of this project ranged from replacing gaskets and wedge plugs, using new sealants or sealing sealants (Gore-Tex type), to overhaul and replacing safety valves of pressure regulators, piston rods, installation of natural gas sensors. Repaired fracturing and GTP equipment components were regularly checked as part of a routine monitoring program to ensure that they did not again become a source of leaks.

Natural gas production and transmission

Reduction of Methane Emissions on the Gas Equipment of Gas-distributing Points and on the Gas Armature of Gas-distributing Networks of PJSC "Mariupolgaz"

The purpose of the project is to reduce natural gas emissions from the gas transmission and distribution infrastructure of PJSC Mariupolgaz as a result of leaks from gas equipment and gas fittings. The main cause of natural gas emissions is the failure of the sealing elements of the equipment as a result of temperature fluctuations and humidity. The removal of natural gas sources has led to a reduction in greenhouse gas emissions.

Details of events/modernization:

- Number of equipment where repairs (replacement) were made, pcs.: 244

- Number of repaired (replaced) gas fittings, pcs.: 6,481

- The introduction of targeted inspection and maintenance of gas equipment and flanged and threaded connections of gas fittings is a modern and most cost-effective practice that allows not only to detect release points, but also to determine their volumes (i.e., the potential amount of gas loss reduction). This key information was necessary to justify the effectiveness of the repair and the priority selection of its objects, i.e. important in case of insufficient funding to eliminate all emissions. This activity included the purchase and calibration of modern measuring equipment, relevant studies of operating parameters, monitoring of gas equipment and gas fittings, flange and threaded connections, the creation of a system for collecting and storing methane sources, as well as conducting internal audits and a system for ensuring the quality of removal and accounting of methane emissions. Measurement of exposure and emissions of methane was carried out by the emission control system on all gas equipment, on gas fittings (bolts, taps, valves), on flanged and threaded connections, including methane emissions removed (equipment elements under repair). The monitoring of which was carried out on a regular basis by specially trained personnel. Detected emissions were labeled accordingly by individual meters, methane emissions were measured and recorded in the database.

- The removal of detected emissions was carried out as a result of the repair of gas equipment and gas fittings on gas pipelines with emissions within the framework of this project and ranged from the replacement of sealing elements or sealing, to overhaul and replacement of gas equipment and gas fittings with new, modern equipment. The repaired units of gas equipment and gas fittings of gas pipelines were regularly inspected as part of the planned control activities to ensure that they would not again become a source of emissions.

Natural gas production and transmission

Reduction of Natural Gas Emissions at OJSC "Odesagas" Gate Stations and Gas Distribution Networks

The goal of the project is to reduce natural gas leaks in the gas transmission and distribution infrastructure of PJSC Odesagas. The main sources of leaks are switch mechanisms (bolts, taps, fittings), flanged and threaded connections of gas pipelines of PJSC Odesagas in the amount of 11,174 pcs., GDP and SRRP in quantity The main reason for the leakage of natural gas is the rapid failure of the sealing elements. The elimination of the methane leak led to a reduction in greenhouse gas emissions.

Details of events/modernization:

- Replacement of points – 11,174 gas fittings in distribution networks.

- Replacement, pcs. – 1,851 GСP and СGCP.

- Implementation of a targeted inspection and maintenance of gas distribution points and cabinet gas distribution points, purchased and calibrated new modern measuring equipment, appropriate employee training, developed monitoring maps with a list of all equipment components subject to regular inspection, creation of a system for collecting and storing data on leaks, and an internal audit and quality system has also been introduced. to eliminate and account for methane leaks.